While safety barriers for buildings are often incorporated at the design stage, there are occasions when a completed building needs retrofitting. This might be due to a safety issue being identified, a need to update to new building codes or simply a desire to improve fall protection.

Where this happens, it’s important to assess the available barrier options and consider how they could impact the existing structure.

Sometimes building owners require the new barrier to look as if it was always meant to be there, rather than something that was added afterwards. If so, the barrier will need to align with the existing building design – or at least not overwhelm it in any way.

One solution is to install a tensile barrier that is light and unobtrusive in appearance while still meeting safety requirements. Stainless steel materials such as Jakob wire rope and Webnet mesh are ideal materials for this scenario – they are highly robust while also being light in appearance and allowing for sightlines and airflow.

Tensile cables and mesh can also keep costs down through faster installation, low maintenance requirements and a reduced need for material. In addition, these materials are highly flexible, customisable and adaptable to all kinds of shapes, sizes, and designs.

Here are some of the things to consider in a retrofit stainless steel tensile barrier and some project examples.

Tensile retrofit barrier options: main considerations

Installing a tensile retrofit barrier requires a robust understanding of how the barrier will affect the existing building. This includes whether it will place any strain on it, and how it will impact existing architectural design.

You may also need to determine if installation could interrupt daily operations and find a way to work around that.

Another crucial consideration is how to integrate a tensile barrier into standard construction – since these are two very different kinds of building systems. This requires an understanding of how tensile systems work (e.g., in terms of loads, movement, and tensioning) and expertise in precision engineering.

The Tensile team has been involved in numerous retrofit barrier projects where we were able to create a custom solution that addressed these types of issues.

Here are a couple of examples.

RFW Children’s Charity, Sydney

Before this building was fully completed, the charity identified a serious safety issue around its spiral staircase and four-storey atrium.

This situation called for a highly bespoke solution, since the barrier needed to adapt to the spiral shapes of the staircase and attach back to the rectangular atrium edges. The client also wanted the barrier to look as if it was part of the original design.

The material chosen for the task was 40mm-aperture Webnet, formed into a kind of corkscrew shape that had never before been attempted in Australia.

The finished product is a unique barrier that provides maximum safety, and looks as if it was always meant to be there!

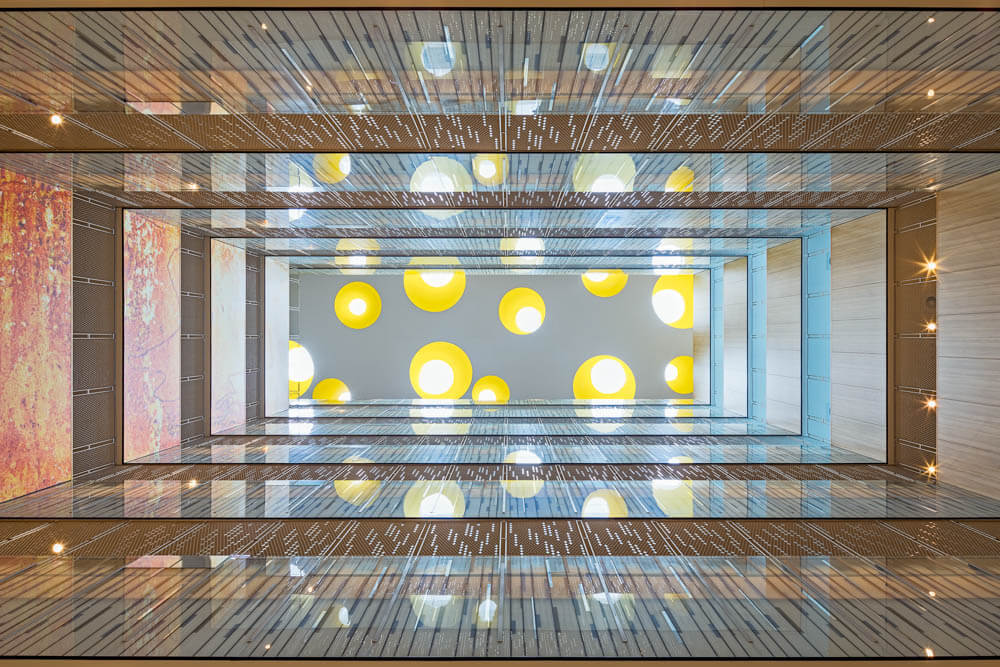

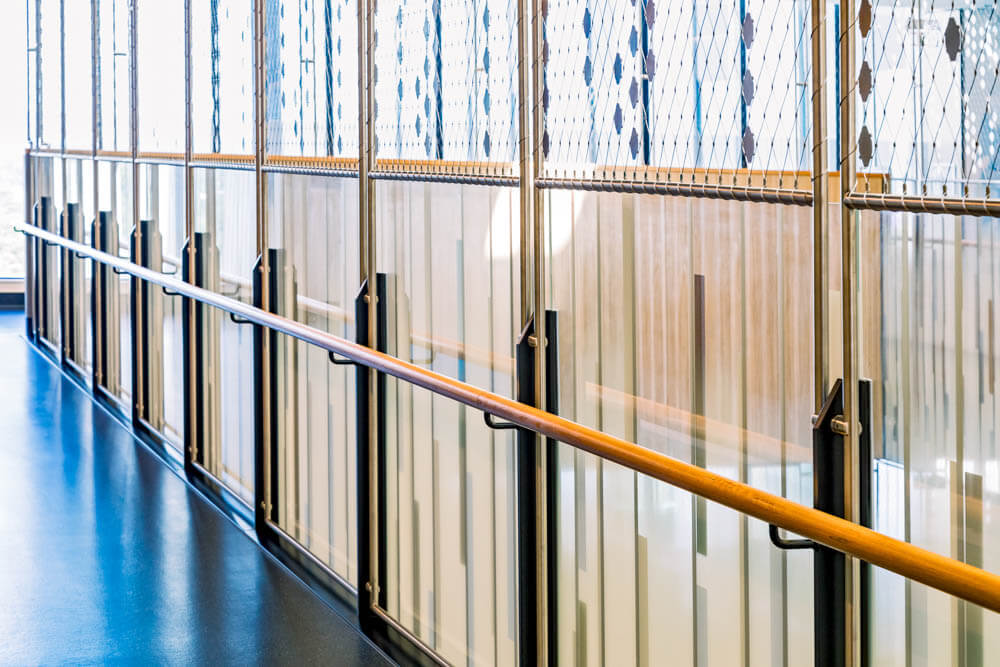

Northern Beaches Hospital atrium, Sydney

This hospital in French’s Forest identified some safety issues around its seven-storey atriums that needed a barrier solution.

The requirement was for barriers that allowed for sightlines and airflow and looked as if they were part of the initial design.

We created the barriers from 60mm Webnet with added decorative plates to reflect the fretwork on the existing glass balustrades.

The Webnet was mounted to stainless steel frames which enabled the bulk of the work to be done offsite, in turn minimising disruption to hospital operations.

The result is a series of full-length non-climbable barriers that not only maximise safety but also look pretty stunning!

Call us about tensile barrier options.

Interested in a retrofit barrier that addresses safety and looks great? Call us today!