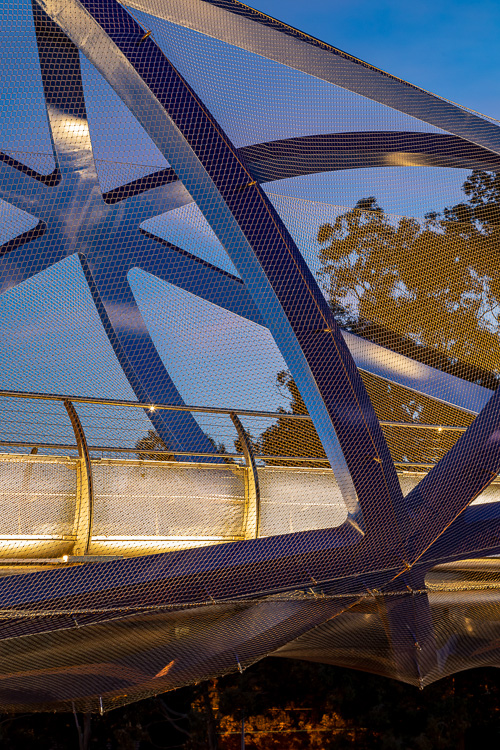

Lachlan’s Line pedestrian and cycle bridge is an award-winning helical-shaped steel structure, bright blue in colour and 178m in length, that connects the Macquarie Park precinct to North Ryde station in Sydney.

Tensile was responsible for the design, engineering, supply and installation of the anti-throw screens around the outside of the bridge.

The bridge is a unique structure – one that required ‘thinking outside the box’ to create!

About the Lachlan’s Line project

Lachlan’s Line was announced by the NSW Government in 2013, with the purpose of transforming a disused industrial site into a sustainable development for the local community. As well as the bridge, the development includes residential apartments, retail spaces, open spaces, parks and playgrounds.

The bridge was built for Landcom, the state government’s development agency. It was created to provide safe access to transport for the precinct’s 5,000 residents.

However, its purpose is more than practical. According to the architect, KI Studio, it was also designed to create a memorable landmark for the region, and to give users the engaging and unique experience of “walking through a sculpture”.

Construction details

The bridge uses flat-plate steel construction and weighs 335 tonnes in total, with the steel fabricated by S&L Steel in Glendenning.

Before final installation, the structure was assembled and dismantled off-site in a trial run. It was then transported and installed into position in four sections by crane, with the mesh screen already in place.

According to Arup, the engineering firm for the bridge, the design is considered the first of its kind in the world. The truss of the bridge “dilates based in its structural demand”, with its diameter varying at different points from 5.5m to 7.8m.

How we made the Webnet screen

The anti-throw screen was created from 2,500m2 of 40mm aperture 1.5mm Webnet mesh, supported on 2,000m of 6mm Jakob cable. It required 2.15km of lacing, which translates to 53,750 diamond shapes!

The mesh was broken into 21 bays, with three pieces per bay, making 63 pieces in total. The pieces were not all the same however – each one was unique and shaped to suit its final position on the bridge. This allowed us to avoid modification of the mesh after the event.

To create the unique mesh pieces, we made complex 3D models of each. These were then flattened out for manufacture.

One of the benefits of being part of the design team was that we were able to adapt our methodology to suit the overall construction process. Pre-installation of the screen saved a lot of time and meant avoiding the need to work over busy roads at night.

A combination of practicality and aesthetics

The completed screen meets Roads & Maritime Services (RMS) standards – the accepted standards for anti-throw screens across the country. This means it provides the anti-fall, anti-throw and non-climbability safety aspects required for the bridge. However, in typical Webnet fashion, it does so without any visual interference to the design.

Jakob’s Webnet is the only material that could have provided the combination of characteristics required for this unique project! This includes shape, strength, transparency, flexibility, longevity and ease of installation.

The completed bridge was the winner for the NSW Steel Excellence Award for Engineering projects for 2020. The Australian Steel Institute considers the project to be a demonstration of how Australia can produce steel fabrication designs on a world class level.

This unique structure is one that no one could fail to notice as they pass through the region, and one we are definitely thrilled to have been a part of!