The support structure, method of installation and how essential ongoing maintenance will be undertaken need to be considered at the design stage.

The support structure

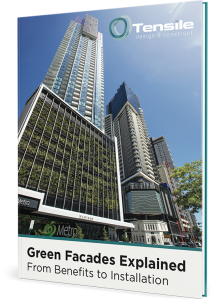

Wind and movement pressures on a multi-storey building mean that a strong support structure for plants is usually required.

Metal support structures are recommended, as wooden and plastic trellises do not have the same resistance to UV light, wind forces and temperature changes. Examples of metal systems include stainless steel cables, mesh or netting, cable lattices and wire rope systems.

It’s essential that the support structure suits the building in question. In a new build, the structure can be incorporated at the design phase. In the case of a pre-existing building, a thorough site assessment is needed to arrive at the most suitable solution.

In assessing a building for a facade, consideration needs to be given to transient loads (e.g. wind, rain and movement) and dead loads (the final weight of the structure, substrate, water and plants).

Pre-tension load also needs to be assessed. This refers to the level of tension held in the support structure. As a general guide, support cables usually have tension of 1-2kN (kilonewtons) and wire mesh systems have pre-tension load of 20-30kg per lineal metre.

Engineering

It’s important that the structure is precisely engineered. For example, support cabling systems need to be engineered to allow for dead weight of plantings at 8kg/m2, with 80% porosity for the plants, while mesh systems need to allow for 20kg per lineal metre.

Support cables for hybrid systems (which involve a mix of methods), also need to be pre-tensioned to 1-2kN and allow for planter unit weights of 60-80kg/m2.

Over-engineering and under-engineering should be avoided – as the first will add unnecessarily to the cost, while the second will result in a system that lacks sufficient strength.

Installation methods

The installation methodology will differ depending on the building. A multi-storey building installation will naturally be more complex than a low-rise one, and this may increase the cost considerably.

A very high building may require heavy equipment such as cranes, swing stages and lifts, as well as a team of workers to get the structure in place.

The methodology will also have an impact on how long the project takes to complete. For instance, working from the inside out on a building is likely to take longer than an installation undertaken from outside alone. A longer completion time means higher costs for labour and equipment.

Maintenance

As for any living system, a green facade will need ongoing maintenance. Typical maintenance tasks include pruning, weeding, fertilising, irrigation, repairs, replacement of plants, and rubbish removal.

The maintenance plan should be factored in at the design stage. The access method for maintenance needs to be considered here.

In a tall building it may involve the use of building maintenance units (BMUs), boom-lifts, or rope systems. With the first two, weight restrictions apply, which means the weight of people, materials and equipment needs to be factored into the maintenance plan. Rope systems are simpler, but tend to be slower and expensive to operate.

Another option is to incorporate a bespoke maintenance system into the support structure, such as a walkway that allows for easy access to the facade and eliminates the need for heavy equipment.

The timing of maintenance will depend on requirements. Different tasks may also be required to be done at different intervals. For example, a maintenance plan may involve doing general inspections monthly, pruning and fertilisation twice yearly, and repairs and reactive maintenance tasks as needed.

For ideas and advice on your next green facade project, reach out to the Tensile team here.

Image source: @hickorygroup